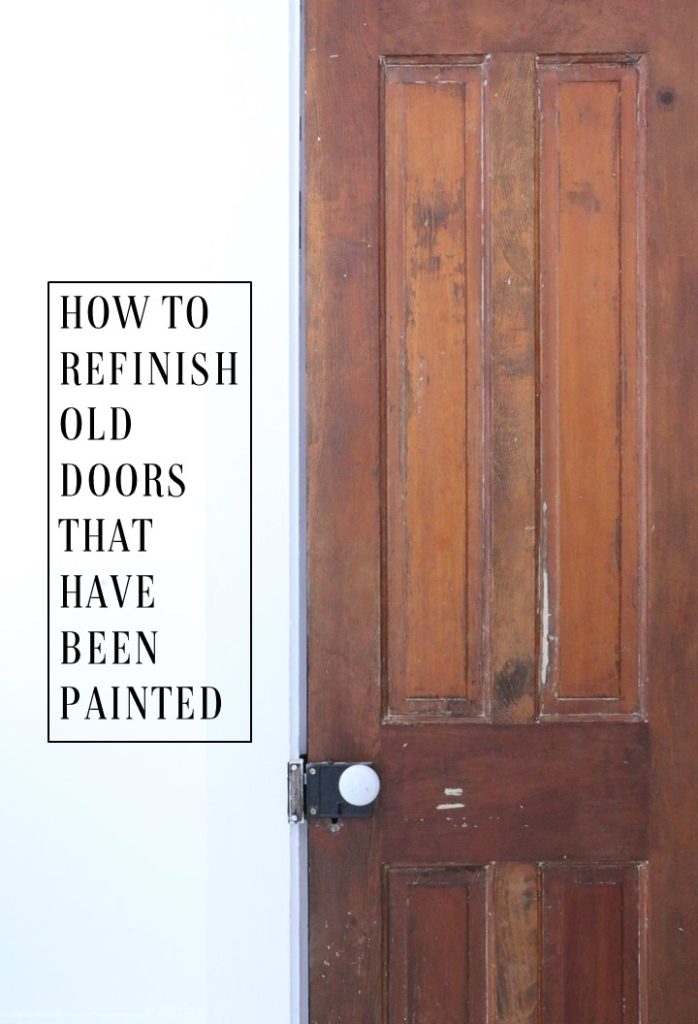

Today’s post has been a long time coming. Because this project is not for the faint of heart. If you live in an old house, chances are, you have old doors. And, if you’re like me, many of those doors have been painted over time and time again. Now, maybe you’re luckier than me and a paintbrush has never touched your wood doors. But about half the doors in our house have been painted. With multiple layers of paint.

We plan on restoring all of them eventually, but hadn’t gotten around to any of it. But, since we’ve been working on the nursery, I figured the best doors to start with would be the two painted doors in there. Now, I’ve stripped a lot of furniture in the last several years, and restored a lot of tables and dressers, but I’d actually never done a door before. So consider this my totally non-professional guide on how to restore doors that have been painted.

Step One

Remove your door from the room that it’s in, and take it somewhere you’ll have room to work. Remove all the hinges and hardware.

Because I’m such a professional blogger I forgot to take a photo of the door while it was still in the room, but here it is outside of my garage before I got started. You can see in the corner of this photo the other door that I was already working one. I did this same process to both doors.

Step Two

If your house was built before 1978, you may have some lead paint. I use these tests to check for lead. Luckily for me, neither of the doors I was working on had lead paint, so that meant I could continue. If your paint tests positive for lead, you may want to consider your options. I would not recommend the following method. If there are multiple layers of paint, the most likely culprit will be the oldest paint, or the bottom layer, so be sure to check that.

Step Three

I found (after some trial and error with paint stripper) that the quickest way to go about removing paint quickly is to scrape it while it’s dry. I tried stripper, which worked, but it seemed to only take off a layer at a time. I found that this set worked well getting off lots of paint at once. The different shaped blades allow you to get into different cracks and crevices along the different surfaces of the door. I didn’t worry about getting 100% of the paint scraped off, but in general I got as much as I could.

Step Four

Sand. Sand like the world is ending. I used my orbital sander, and sanded first with a course 60 grit sandpaper to get the last of the paint off. On the edges of the panels where the orbit sander couldn’t reach, I sanded by hand. Once all the paint was off, I repeated the sanding with a 120 grit sandpaper and a 220 grit sandpaper.

Step Five

I used steel wool and mineral spirits to scrub the door one last time after all the scraping and sanding. Now, keep in mind, these steps took me like two weeks. I work in limited time shifts during naps and after toddler bedtime, so a normal schedule might allow this to get done in a matter of days, but I was averaging two weeks per door.

Step Six

This would be optional based on your wood and your preferences. I had one door in the room that was untouched, and I wanted the three doors I was working on to be all about the same color. So I used the stain we used on our floors throughout the house (Minwax Early American) and it ended up being a pretty close match to the door that was already in the room. I prefer to use a rag to apply (with rubber gloves on!), rather than brushing and wiping the excess. I just apply with the rag and rub it in immediately. If you like the color of your wood after you strip it all down though, you could totally skip this step.

Step Seven

The last thing I did was put a coat of Polyurethane on them. I like to buy the cheap paint brushes to apply the poly, and then just throw them out when I’m done. I ended up doing just one coat of poly (again, trying to match an existing finish!). I let the first side dry for 24 hours, then flipped the door around and did the other side. I let it sit for another 24 hours before moving them back into the room.

Step Eight

Bring your doors back into place, and re-install the hinges and doorknobs. And for goodness sake enjoy the fruit of your labor!

The door on the right is the entrance to the room, and the door on the left is one of the ones that were painted. There are a couple of white spots that you can see which are actually wood filler. They aren’t perfect…they’re 125 year old doors that had six coats of paint on them! But for goodness sake I think they turned out pretty good.

This door on the other side leads to the bathroom, and is the one from the first picture. Let me show you again:

Can you even believe that wood grain was hiding under all those layers of paint?!

This project was a doozy, I’m not gonna lie. It was weeks worth of work, sweating it out in my hot garage in a mask and protective gear. It wasn’t a fun DIY. But, they are back to the way they were intended to be in this house, and I think that’s what matters. And I’m stinking proud of the work that went into these. So, do you have any doors that need refinishing? Are you brave enough to take it on? (I totally think you can!) That’s all for today, friends! Have a fabulous day!

9 Comments

I have the exact same door that you have in the picture with the 4 panels on it. I have been working many hours on the door, about to give up. I really like the look it has but tired of scraping and using a heat gun and using a stripper and steel wool, I have tried so many things but there are some stubborn spots of paint that I’ve even tried sanding. I’m almost ready to go out and buy a whole new door but don’t want to do that. I’m not sure what to do with it. Thinking about repainting it just so I don’t have to worry about those few spots that I can’t get the old paint off and that varnish that must have been used as the very first layer. With my house being so old, the doors are not ones that you can actually just go out to buy. The measurements are all off. I have a couple of these doors and luckily I started with just one, I don’t think I will be doing the others now.

You did a great job on yours and wish mine would come out that way.

Don’t use a stripper, use a belt sander. I had 4 coats of paint on top of stain and polyethylene. Then after I got most of it out. I used a hand sander, then just a manual sanding brick for those details. Took a few hours and it was completely clean. I also scrapped after the belt and it took off the last little bits. The hand sander is for making it smoother. Just some tips, we are redoing an entire house that hasn’t been lived in for 10 years. So it’s been a lot of work.

shaft balancing

Shaft Balancing: Achieving Precision and Smooth Operation

In the world of machinery, the efficiency and longevity of rotating parts hinge on a process known as shaft balancing. When applied correctly, shaft balancing eliminates vibrations that can lead to wear and tear, ultimately resulting in a smoother operational experience. Understanding the intricacies of shaft balancing is essential for industries ranging from manufacturing to energy production and agriculture.

The Importance of Shaft Balancing

Every rotating component, be it a fan, turbine, or auger, is susceptible to imbalance due to weight distribution irregularities. Static balance occurs when the rotor is at rest, prompting gravity to pull down the heavier side. Conversely, dynamic balance takes center stage during operation, as centrifugal forces highlight mass discrepancies across different planes. Thus, dynamic shaft balancing is vital for maintaining operational integrity and prolonging the lifespan of rotating equipment.

A Journey Through the Shaft Balancing Process

Dynamic shaft balancing involves a systematic approach to rectify imbalances through sophisticated instruments like the Balanset-1A. This device serves multiple applications, ensuring versatility and effectiveness across various types of rotors found in modern machines.

Step 1: Initial Vibration Measurement

The balancing journey begins by mounting the rotor on a specialized balancing machine. By connecting vibration sensors to the rotor, an operator can record the initial vibrations when the device is powered on. This measurement acts as a baseline for all subsequent adjustments.

Step 2: Installing Calibration Weights

Once the initial vibrations are logged, the next step involves the application of a calibration weight. This known mass is temporarily secured on one side of the rotor, allowing the system to capture the ensuing vibration changes. By carefully monitoring these alterations, technicians gain insight into how the weight influences overall balance.

Step 3: Adjusting the Calibration Weights

The calibration weight is then relocated to different points on the rotor to further analyze the impact on vibrations. This repositioning is crucial in pinpointing where corrective measures need to be applied for effective balancing.

Step 4: Final Weight Installation and Balance Check

With vibration data gathered from various points, the next step is to determine the necessary corrective weights for optimal balance. Once these weights are installed, the rotor undergoes a final check to confirm that vibrations are minimized. A successful balancing operation will exhibit significantly reduced vibration levels, signifying that the shaft is well-balanced and primed for smooth operation.

Understanding Mass Adjustments

The effectiveness of shaft balancing relies heavily on understanding the relationship between weight and angle installation. When addressing imbalances, technicians must consider the positions where weights need to be added or removed, often exemplified through the balance process diagrams and measurements. Corrective weight installations must align precisely in the direction of the rotor’s rotation, enhancing balancing effectiveness.

Applications of Dynamic Shaft Balancing

The utility of shaft balancing extends beyond traditional manufacturing, finding applications in various industries including:

Agriculture: Machinery like combines and mulchers benefit greatly from balanced shafts, ensuring efficient operation in often challenging conditions.

Energy Production: Turbines and other rotating components in power generation require meticulous balancing to reduce downtime and enhance efficiency.

Manufacturing: Crushers and fans utilized in production lines see improved reliability and longevity with regular balancing practices.

Conclusion: Embracing Precision in Shaft Balancing

In conclusion, shaft balancing is a critical practice to ensure the reliability and efficiency of rotating machinery across various sectors. By understanding the principles of static and dynamic balance, alongside employing advanced tools like Balanset-1A, technicians can significantly reduce vibrations, promoting enhanced performance. Investing in proper shaft balancing not only leads to smoother operations but also extends the lifespan of critical machinery, creating a more efficient and sustainable workflow.

https://femalecricket.com/women-cricket-news/54143-top-features-of-the-1xbet-app-you-should-know-about.html

I am sorry, this variant does not approach me.

[…] Old doors and windows are architectural relics that carry the weight of history, making them excellent choices for upcycling into functional art pieces. Their distinctive frames and intricate details provide the perfect canvas for creative reinterpretation. […]

field balancing

Field Balancing Solutions for Reliable Equipment Performance

Field balancing is an essential service for optimizing the performance of various industrial equipment, including fans, forestry mulchers, and more. This process focuses on eliminating both static and dynamic imbalances, which can lead to excessive vibration, decreased efficiency, and ultimately, equipment failure.

Understanding the Importance of Field Balancing

In industries where machinery operates continuously, balancing is critical. Over time, equipment can develop imbalances due to wear and tear, improper installation, or other operational factors. Field balancing services ensure that your equipment operates smoothly, reducing vibration levels, extending the lifespan of machinery, and minimizing the risks of breakdowns.

Our Field Balancing Services

Our company specializes in providing professional field balancing services throughout Portugal. We focus on various types of equipment, including:

Industrial fans

Forestry mulchers

Combine harvesters and crushers

Grain harvesting equipment rotors

Other machinery parts and components

Advanced Equipment and Techniques

We utilize state-of-the-art portable balancing equipment and vibration analyzers, such as the Balanset model, for effective on-site dynamic balancing of rotating machinery. This ensures that we can tackle imbalances without the need for costly transportation of equipment to a separate facility. Our modern techniques align with international standards, including ISO 10816, ensuring high-quality results that you can trust.

Our Comprehensive Maintenance Approach

Field balancing is more than just correcting imbalances; it’s about maintaining reliability and efficiency. We provide a comprehensive maintenance approach that includes not only balancing but also diagnostics to prevent potential malfunction. By prioritizing equipment health, we help maximize uptime and minimize economic losses, which is crucial in fast-paced industries.

Personalized Service for All Clients

No matter the size or type of your business, our field balancing services are available for everyone. We pride ourselves on delivering a personalized approach tailored to the unique specifications of your equipment. Our team works closely with you to determine the best solutions that fit both your operational needs and budget constraints.

Cost-Effective Solutions

The cost of our field balancing services is based on several factors, including the distance and any transportation requirements. We strive to offer some of the most cost-effective solutions on the market, ensuring you receive exceptional service without straining your budget.

Why Choose Our Field Balancing Services?

Choosing our field balancing services is a proactive step toward safeguarding the longevity and reliability of your equipment. Our commitment to quality means we provide a guarantee on all work performed. If you’re looking to keep your machinery in optimal condition and running efficiently, don’t hesitate to request a visit and diagnosis today.

Field Balancing Price List

Our pricing structure for field balancing services is straightforward, ensuring transparency for our clients. Here are typical costs for common machinery:

Fan (0-15 kW): €500

Fan (15-75 kW): €700

Fan (75-300 kW): €900

Harvester straw chopper: €500

Harvester threshing rotors: €900

Mulcher rotor: €700

Other rotors: €500-900

Fan Impeller Balancing Criteria

When it comes to fan impeller balancing, we adhere to specific criteria to classify machine performance:

Machine Class

Good

Admissible

Still Admissible

Inadmissible

Class 1

< 0.7

0.7-1.8

1.8-4.5

> 4.5

Class 2

< 1.1

1.1-2.8

2.8-7.1

> 7.1

Class 3

< 1.8

1.8-4.5

4.5-11

> 11

Class 4

< 2.8

2.8-7.1

7.1-18

> 18

Stay Ahead with Professional Balancing

In an era where machinery efficiency directly correlates to productivity, field balancing emerges as a crucial preventive measure. Invest in our services to ensure that your equipment operates at peak performance. The sooner you address field balancing, the longer your machinery will serve you, fostering a healthy work environment that mitigates unplanned downtime.

http://ivbud.com/interesting/9240-ventyliatsiia-ta-dymokhid-u-bahatokvartyrnomu-budynku-iak-zabezpechyty-bezpeku-i-dovhovichnist-system

Watch YouTube Short

Understanding the Balanset-1A: A Comprehensive Guide to Rotor Balancing

The Balanset-1A is an advanced device designed for the precise balancing and vibration analysis of rotors. This two-channel device is versatile, capable of managing various rotor types, including those found in crushers, fans, mulchers, choppers used in combine harvesters, shafts, centrifuges, and turbines. But what is the procedure for balancing a pump unit? This article will delve into the Balanset-1A’s features and guide you through the balancing process.

Features of Balanset-1A

The Balanset-1A offers both vibrometer and balancing modes, providing a comprehensive solution for rotor maintenance.

Vibrometer Mode:

Tachometer: Accurately measures rotational speed (RPM).

Phase: Determines the phase angle of vibration signals for precise analysis.

1x Vibration: Measures and analyzes the fundamental frequency component.

FFT Spectrum: Offers a detailed view of the frequency spectrum of vibration signals.

Overall Vibration: Monitors the overall vibration levels.

Measurement Log: Stores data for future analysis.

Balancing Mode:

Single Plane Balancing: Balances rotors in a single plane to reduce vibration.

Two Plane Balancing: For dynamic balancing across two planes.

Polar Graph: Visualizes unbalance, aiding in accurate weight placement.

Restore Last Session: Resume previous sessions conveniently.

Tolerance Calculator (ISO 1940): Calculates acceptable balancing tolerance.

Grinding Wheel Balancing: Utilizes circular groove with three counterweights.

Additional features include comprehensive charting options, an archive for session storage, detailed report generation, and re-balancing capabilities. The device supports both Imperial and Metric systems, ensuring global compatibility.

What is the Procedure for Balancing a Pump Unit?

Before initiating the balancing process with the Balanset-1A, ensure the mechanism is in good technical condition and securely mounted. Any necessary repairs should be completed first. The rotor should be free of any contaminants that could interfere with the balancing process.

Begin by selecting appropriate locations for the placement of vibration and phase sensors, following the recommended guidelines. Prior to balancing, conduct measurements using the vibrometer mode. If the overall vibration closely matches the rotational component, the rotor’s imbalance is likely the primary contributor to vibration. Should the overall vibration significantly exceed the rotational component, further inspection of the mechanism is advised. This includes checking bearing conditions, foundation stability, rotor clearance, and external vibration influences.

Analyzing temporal function graphs and vibration spectra can be beneficial in diagnosing issues. Additionally, ensure there is no significant static imbalance by manually rotating horizontally oriented rotors 90 degrees. If static imbalance is present, the rotor will rotate to a position of equilibrium. Add a balancing weight to the upper midpoint of the rotor’s length to maintain its static position. This preliminary balancing reduces vibration during initial operations of highly unbalanced rotors.

Conclusion

The Balanset-1A is a powerful tool for ensuring the smooth operation of rotors across various industrial applications. By following the outlined procedures and utilizing the device’s extensive features, technicians can achieve precise rotor balance, thereby enhancing machinery performance and longevity. For anyone involved in rotor maintenance, understanding the Balanset-1A’s capabilities is essential for achieving optimal results.

[b]Contact Information:[/b]

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on Facebook Marketplace

Balanset-1A OEM on Machinio